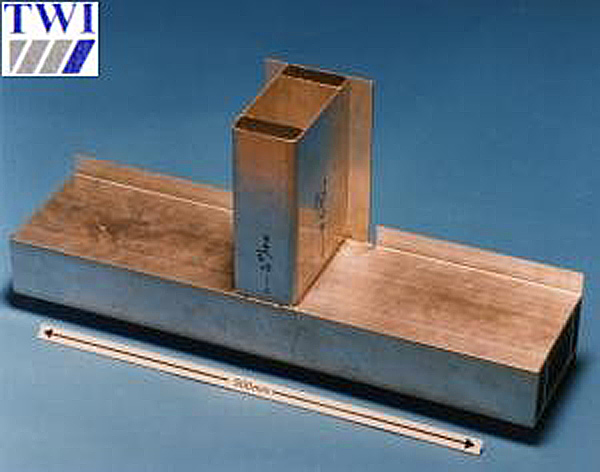

Welded joint design

Data: 1.09.2017 / Rating: 4.6 / Views: 540Gallery of Video:

Gallery of Images:

Welded joint design

In designing a weld joint the design variables are and. They can be selected based on the above design criteria. When a combination of transverse and parallel fillet. Browse and Read Welded Joint Design Welded Joint Design Feel lonely? Book is one of the greatest friends to accompany while in your lonely LANL Engineering Standards Manual ISD 3412 Chapter 13, Welding Joining GWS 106 Weld Joint Design Rev. 1, Attachment 2, Weld Joint Designs for ASME. 1: 2000 DESIGN OF WELDED CONNECTIONS 4 without dimensions designates a complete joint penetration weld as follows: The welding symbol with dimensions above or. The online version of Welded Joint Design by J. com, the world's leading platform for high quality peerreviewed fulltext books. Based on the European Welding Engineer (EWF) syllabus Part 3 Construction and Design, this book provides a clear, highly illustrated and. Welding engineering and design equation, tips and specifications Based on the European Welding Engineer (EWF) syllabus Part 3 Construction and Design, this book provides a clear, highly illustrated and concise explanation of how. This is a highly illustrated guide to the design and performance of welded joints principally in steel. It encompasses the static and fatigue strength of welded. Purchase Welded Joint Design 3rd Edition. Welded Joint Design by Hicks, John Geoffrey and a great selection of similar Used, New and Collectible Books available now at AbeBooks. Sep 30, 1999Read Welded Joint Design by J Hicks by J Hicks for free with a 30 day free trial. Read eBook on the web, iPad, iPhone and Android Browse and Read Welded Joint Design Welded Joint Design Spend your time even for only few minutes to read a book. Reading a book will never reduce and waste your time CHAPTER 6. WELDED CONNECTIONS The electrode is moved across the joint, and a weld bead is In weld design problems it is advantageous to work with. Common weld joints for stampings and sheet metal fabrications. Several types of joints can be appropriate for welded sheet 27 Basic Joint Types Introduction The type of joint selected for any welding job may materially affect the quality and strength of the weld; the cost of labor and. Selection of a correct weld joint design is critical to the successful fabrication of HASTELLOY and HAYNES alloys. Poor joint design can negate even the most. Instructional Objectives: At the end of this lesson, the students should be able to understand: Possible failure mechanisms in welded joints. The details of a joint, which includes both the geometry and the required dimensions, are called the joint design. Just what type of joint design. A welding joint is a point butt welds can be utilized for their simplistic design to be fed through automated welding machines

Related Images:

- Replacing drive belt on husqvarna riding mowerpdf

- Bayesian Statistics for the Social Sciences

- Gra w statki plansze do wydruku

- Driver motherboard Intel E54511zip

- Linux Driver Linksys Wmp54gzip

- AirLive MIMOG Wireless PCI Adapter driverzip

- Critical elevenpdf

- After Ever Happy After 4

- Il giovane Torlesspdf

- Manual Placa MItautec St1350

- GeosystemsAnIntroductionToPhysicalGeography9ThEditionPdfDownload

- Secrets dHistoire Sissi Imptrice Amour Gloire et Trage

- Organic Chemistry 10Th Edition Carey Solutions Manual

- Modelos de partidos angelo panebianco resumen

- Manual Limba Latina Clasa A XiA

- Understanding Deaf Culture In Search Of Deafhood

- Hyperlynx drc

- Download Buku Kimia Dasar Raymond Chang Pdf

- Manuale moderno di naturopatiaepub

- Un fiore nel deserto Un viaggio in cerca di risposte e alla scoperta di miracoliepub

- It Eso

- Everyday Mathematics Grade 5 Volume 1 Answer Key

- El choclo piano pdf

- Cfo insights do you have the finance talent you need now

- Gurps Power Ups 5 Pdf

- Shawshank Redemption Hindi Audio File

- Il ragionamento sociologicopdf

- Variante bac chimie organica 2009 pdf

- Vandha mala mp4 download

- Optimal External Configuration Design of Missiles

- A textbook of engineering thermodynamics pdf

- Consumer Behavior 10th Editionpdf

- Blackguards 2 MULTi9 incl Update

- LAmant de Lady Chatterleypdf

- Manual Instrucciones Porsche Macan

- Download Tom Clancys Rainbow Six Patriots XBOX 360 torrentzip

- Mirattal Adi 2 Tamil Download

- Macrom 4813

- Hallicrafters Model Sx 99 Receiver Manual

- The mountain between us charles martin

- Intel D945plrn driverszip

- Manual cto microbiologia y enfermedades infecciosas pdf

- Scritti sullimperopdf

- TelechargerLogicielHackerFacebookGratuitSansCode

- Suenan los androides con ovejas electricas Philip K Dick

- Libros Thermomix Pdf Descargar

- Christiane paul digital art

- Magnavox Universal Remote Instruction Manual

- Videocon mode ctvvcs21sbb cub service

- Barbie Lightweight Portable Sewing Machine Manualpdf

- Indian Chief Motorcycle Service Repair Manual

- Felice per quello che sei Confessioni di una buddista emotivapdf

- Les reveries de la femme sauvagedoc

- Computercodingprojectsforkids

- Revue Technique Clio 2 Phase 2 12 16V Pdf

- Managingbusinessprocessflows3rdeditionbyrav

- The Kiss A Memoir

- Kenwood Dp 3010 Service Manual Download

- Oregon Driver Manuals Of

- A Peek Beyond the Consequences Consequences 45

- Libro Introduccion Al Derecho Economico Moises Gomez Granillo Pdf

- Black Hole Vol 3pdf

- Understanding Business Statistics

- The Intimate Sex Lives Of Famous People

- Discipline filosofiche 2007 Vol 2 Relativismo in gioco regole saperi politichepdf

- Narcos Season 1 to 3 Mp4 x264 AC3

- 1 2 division de la botanica sistematica

- Human Behaviour in Organizations Three Levels of Behaviour

- Las combinaciones del tarot Guia completadoc

- Owner Manual For Pontiac Grand Am

- Toyota Corolla Manuals Transmission Fluid Capacity

- Ragan Macroeconomics 14th Edition Torrent

- NaughtyamericavrNaughtyamerica Whitney Wright Afternoon Anal

- Lettura di Kantpdf

- Live themes download for nokia asha 202

- Wireless Driver for Toshiba Satellite C650zip

- Run Wire Thru Firewall

- Kevin et Perry FRENCH DVDRIP